INSTALLATION GUIDE

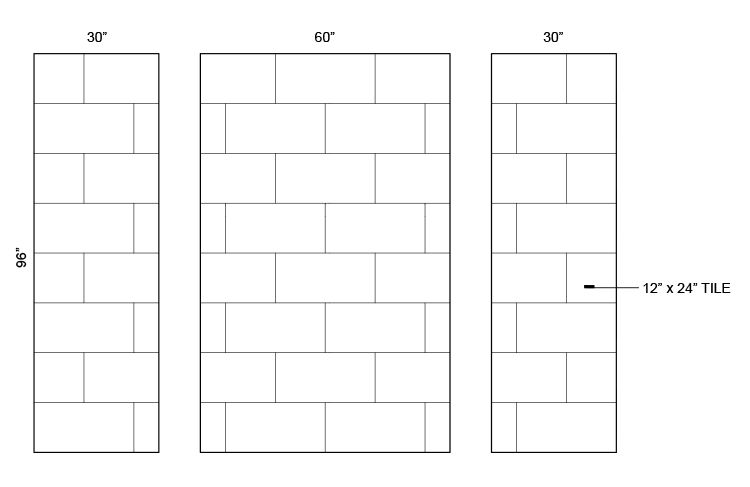

Standard 3-Piece Cultured Marble Panel Specifications

This installation guide applies to all standard 3-piece panel systems

extending to the ceiling where each wall is manufactured in one piece.

General Notes

Prior to starting the installation, please read the notes below as they will help plan your installation and avoid unnecessary breakage. Architectural Concepts is not liable for breakage due to mishandling or improper installing.

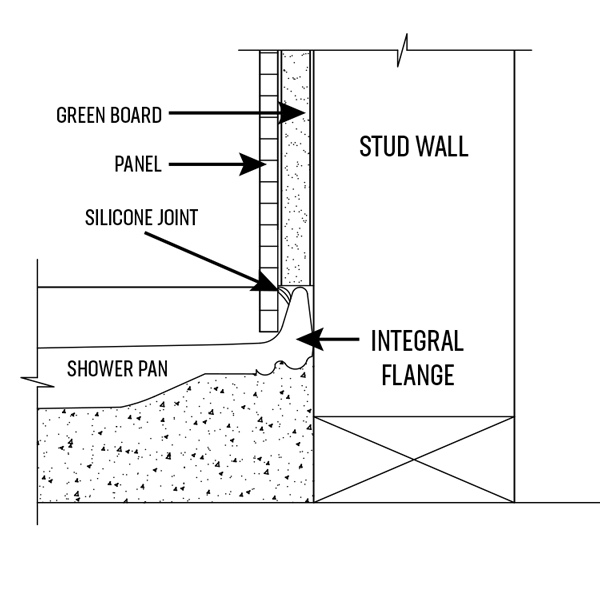

The shower pan should always be set in place, prior to the wall substrate being installed. The shower pans have attached flange to prevent leakage. The wall substrate shall at least cover the thickness of the flange so the panel system remain flush against the wall and prevent the panels to bow out at the bottom. To ensure panels to install properly, provide additional piece of wall substrate if flanges are not completely covered. SEE DETAIL IN STEP 1 FOR ILLUSTRATION.

Handling the material in extremely cold temperatures requires extreme caution, as the panels are more fragile in extremely cold temperatures. When possible, store all material in a heated area at least 24 hours prior to being handled for installation.

If installing grab bars blocking shall be placed in the desired location prior to the wall substrate being installed. Once panel is installed, all screw holes shall be predrilled through the panel, so the screw can pass freely through the panel and into the blocking. The holes shall be drilled slightly larger than the screw, to avoid any part of the threads coming in contact with the panel. The panels are not designed to support the tension placed on the bar. Tighten all screws with caution as the panels can be cracked or broken if the screw is over tightened.

If planning to install the panel system over existing tile, make sure the tile is free of mold and mildew and that all tiles are still well adhered to the substrate. Follow all standard instructions for cutting and installing, with the exceptionof the adhesive to be used. When installing against existing tile, use only 100{1fa982495514e501141dcc8d9a590336921c8ebd75a9bb2a135c5940f6282577} Silicone. The Silicone will provide better adhesion to the tile than will construction adhesive.

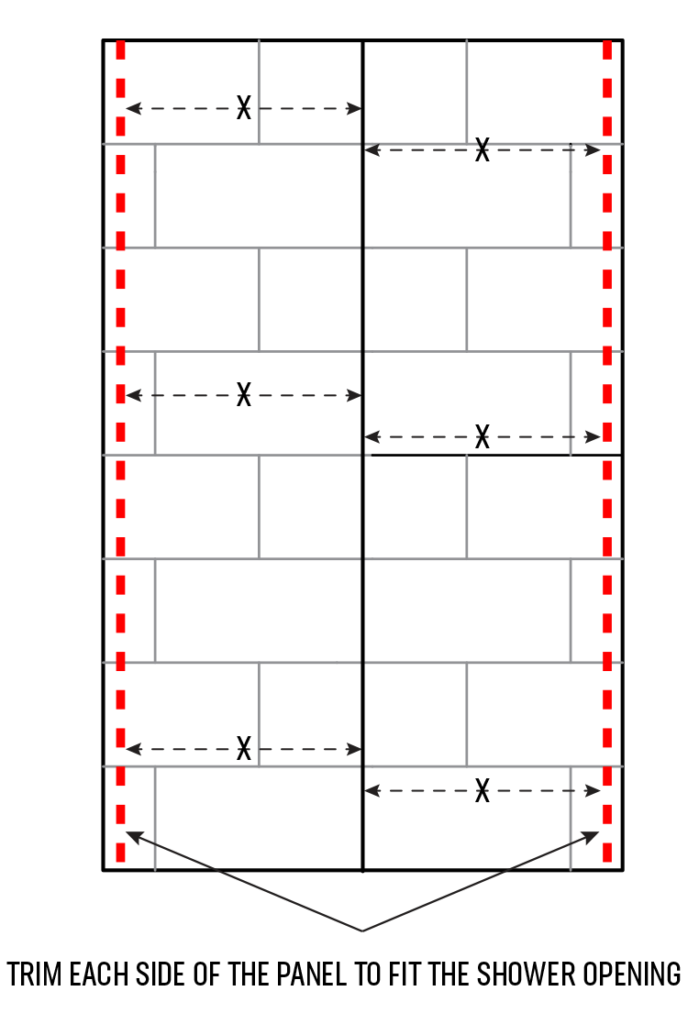

If installing a tile pattern panel system, please follow all instructions closely. The grout joints will not align from panel to panel, unless they are installed exactly as instructed. This is the single item that creates the largest number of customer complaints and requires the purchase of additional material. In ALL cases, where the joints are misaligned, the material was installed in a manner other than the one explained in this installation guide. Generally, panels must be cut on all sides in order to be installed correctly.

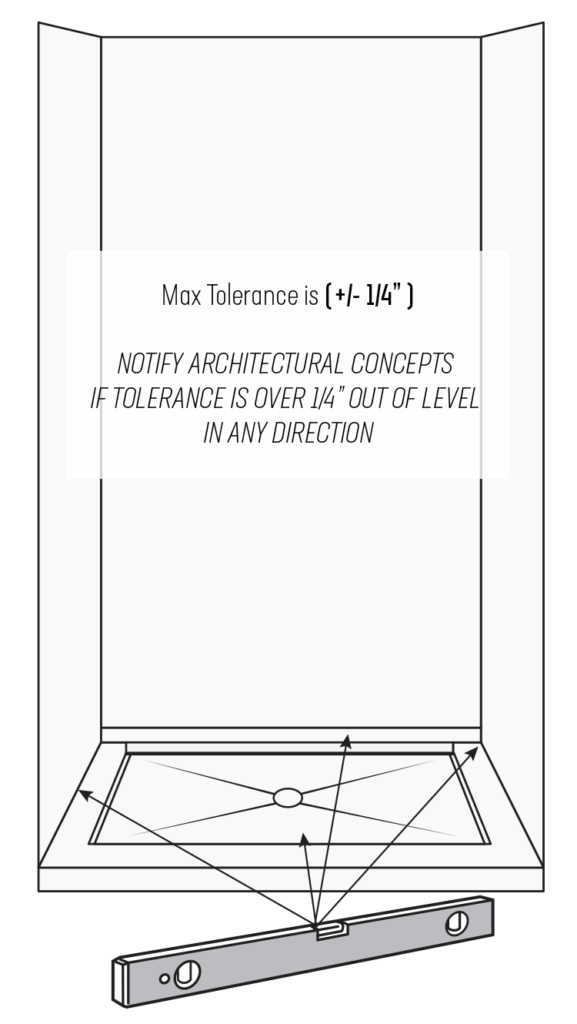

1. Level Shower Pan

Verify shower pan is leveled front to back and side to side.

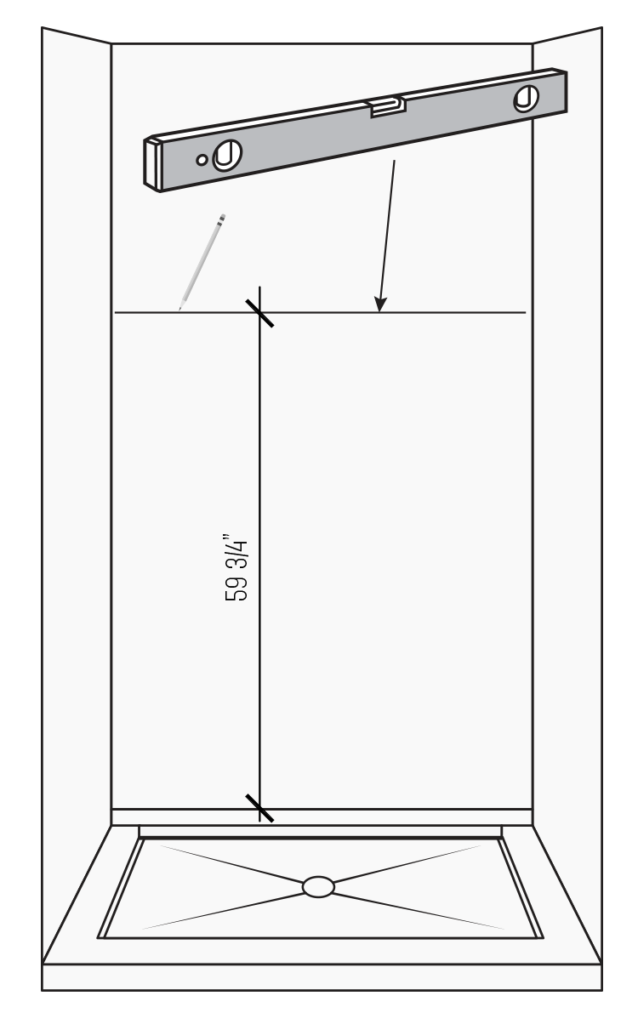

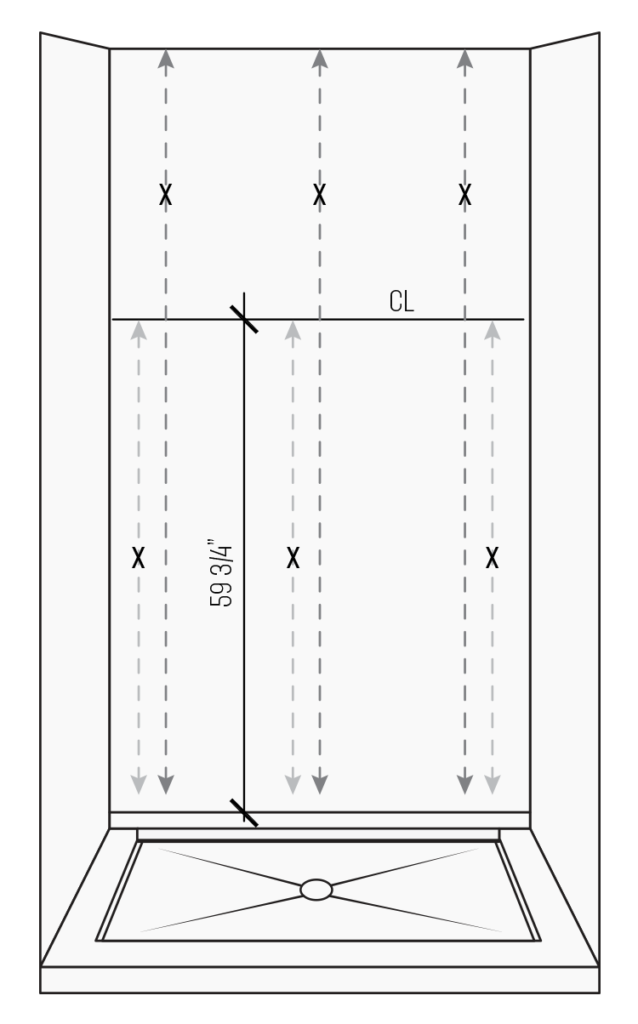

2. Locate Control Lines

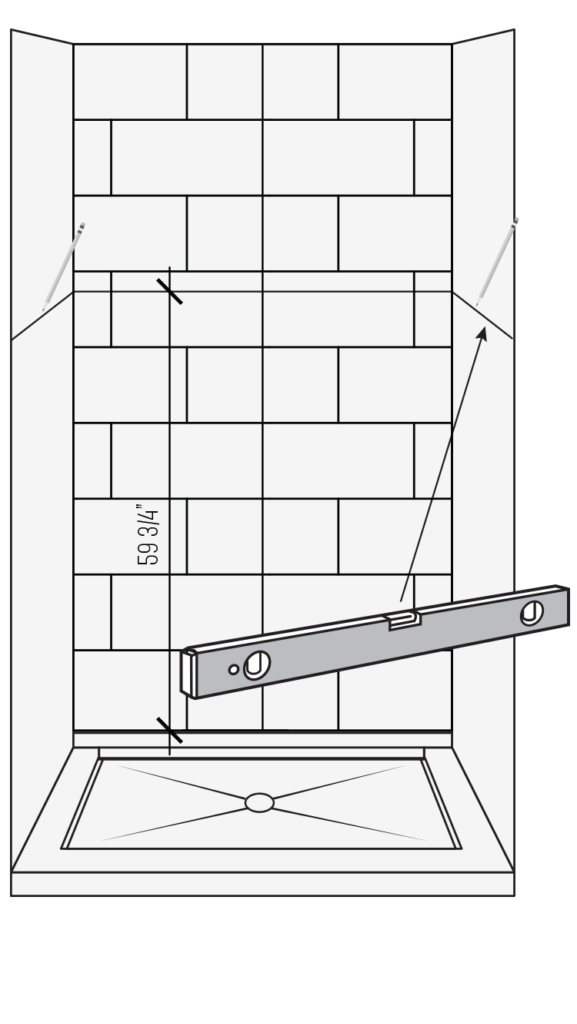

LOCATE A HORIZONTAL CONTROL LINE (CL) WHICH WILL BE USED THROUGHOUT THE INSTALLATION TO SURE PANELS FIT AS DESIGNED.

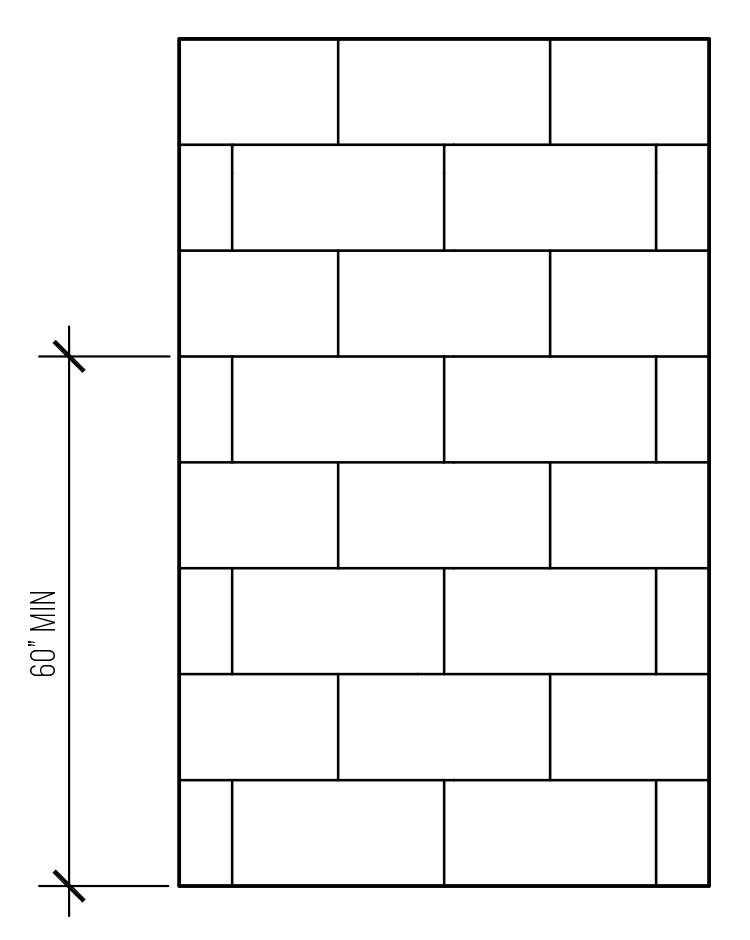

MEASURE FROM THE BOTTOM OF THE BACK PANEL TO THE CENTER OF THE GROUT LINE CLOSEST TO 60”. ONCE MEASUREMENT IS MADE, SUBTRACT 1/2” FROM THAT MEASUREMENT. 1/2” IS FOR ADJUSTMENT.

EXAMPLE:

If grout line measurement is 60 1/4″, then subtract 1/2″. This will give a measurement of 59 3/4″ to place a mark on the wall.

ONCE A MARK IS PLACED, USE THE LEVEL TO DRAW A LEVEL LINE ACROSS THE BACK WALL. THIS LINE WILL BE THE CONTROL LINE (CL)

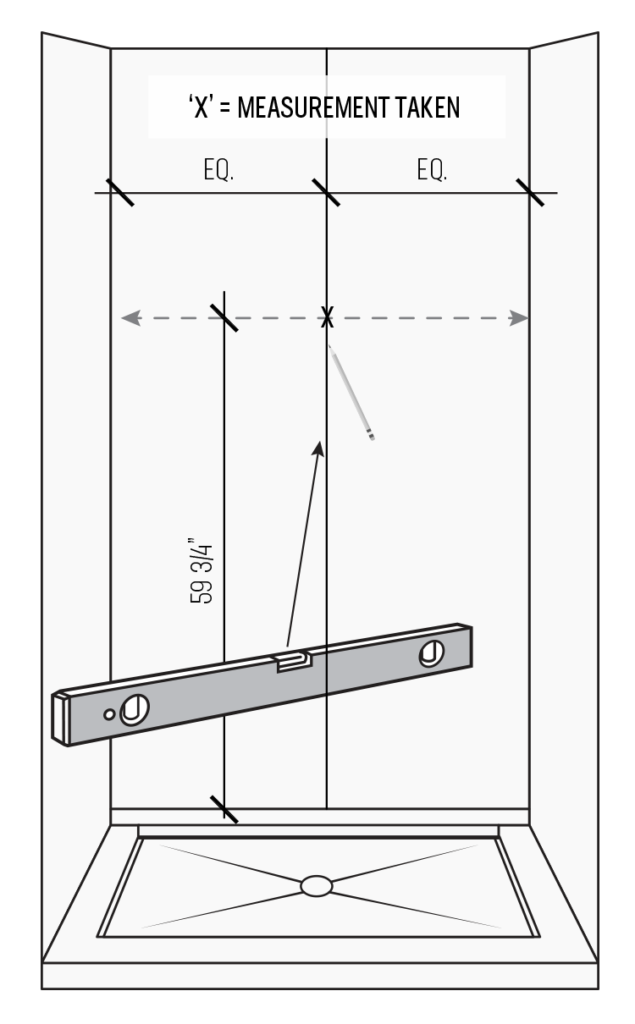

3. Locate Vertical CL

LOCATE THE VERTICAL LINE BY MEASURING FROM THE SAME HEIGHT AS THE HORIZONTAL CL TO THE CENTER OF THE BACK WALL FROM LEFT TO RIGHT AND MARK THE CENTER. USE THE LEVEL AND DRAW A PLUM LINE DOWN THE CENTER OF THE WALL FROM TOP OF PAN TO THE CEILING. THIS CL WILL ESTABLISH WHERE THE SIDE PANELS WILL END.

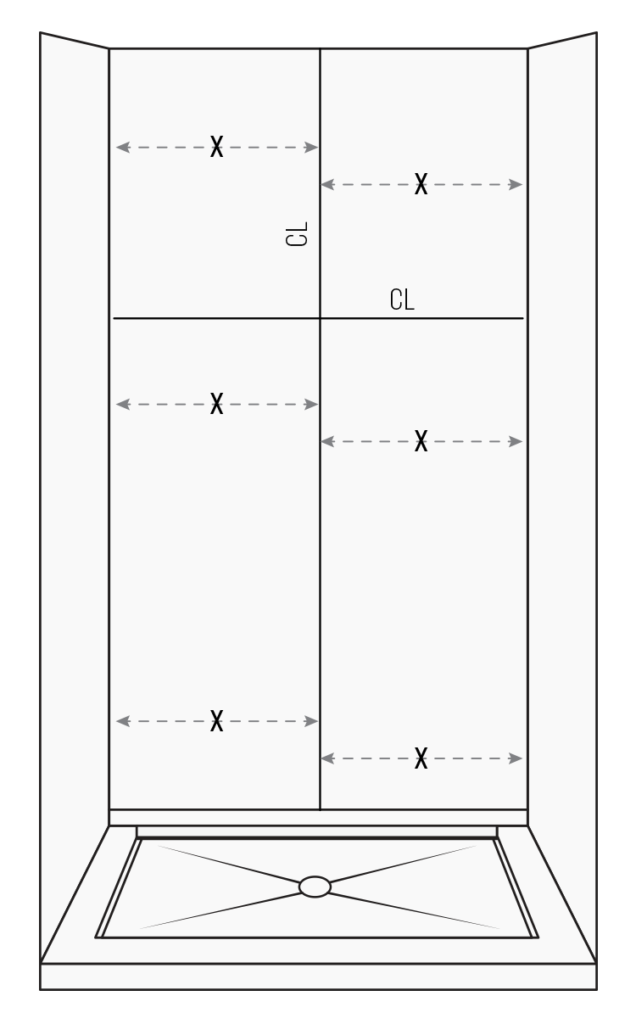

4. Fitting Back Panel

‘X’ = MEASUREMENT TAKEN

USING THE CL AS THE GUIDE, MEASURE FROM THE TOP OF THE SHOWER PAN UP TO THE CL ON THE BACK WALL ON THE LEFT SIDE, RIGHT SIDE, AND MIDDLE. ALSO, MEASURE FROM THE TOP OF THE SHOWER PAN TO THE CEILING IN THE SAME THREE LOCATIONS.

USE THE VERTICAL CL TO LOCATE THE WIDTH. MEASURE FROM THE TOP, BOTTOM, AND MIDDLE, ON BOTH THE LEFT SIDE AND THE RIGHT SIDE OF THE VERTICAL CL.

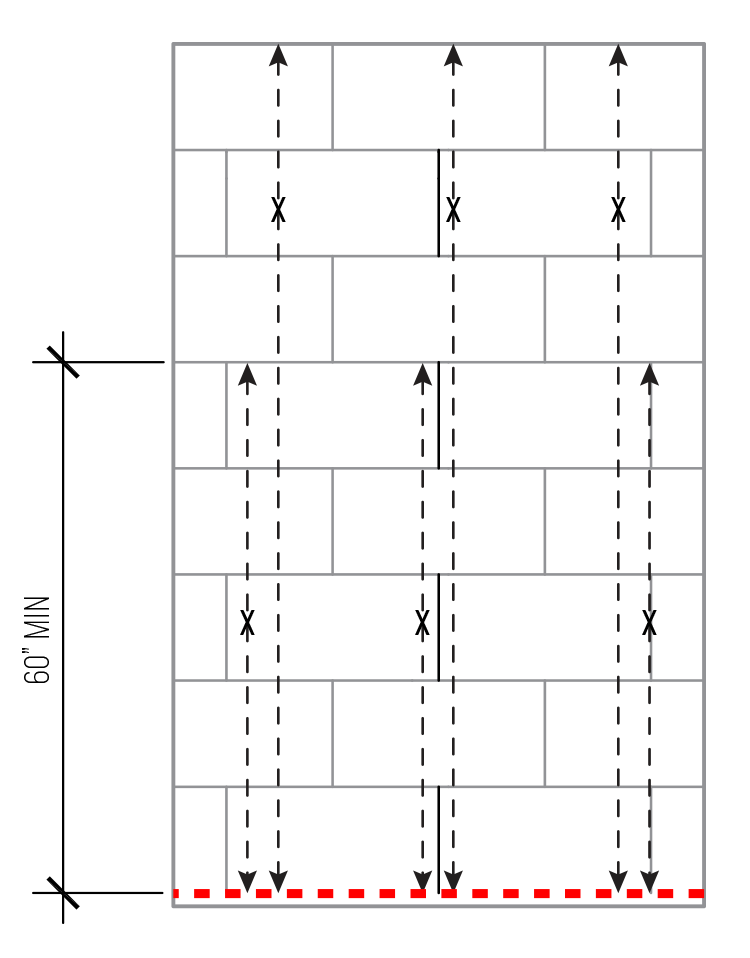

5. Cut the Back Panel

BEGIN BY CUTTING PANEL AT THE BOTTOM. DEPENDING ON WHETHER THE WALLS & PAN ARE OUT OF PLUMB DETERMINES HOW MUCH TRIMMING WILL BE NECESSARY.

TRANSFER THE MEASUREMENTS FROM STEP 4 TO THE FRONT SIDE OF THE BACK PANEL. USE THE GROUT LINE WHERE THE CL LINE WAS OBTAINED IN STEP 2 THAT MEASURES CLOSEST TO 60” AS IT WILL BE EASY TO TRANSFER ALL ESTABLISHED POINTS USING THIS GROUT LINE AS THE CL.

FIRST, MEASURE FROM THE CL DOWN AND PLACE A MARK AT EACH ESTABLISHED POINT. THEN TAKE A STRAIGHT EDGE AND PENCIL TO CONNECT THE DOTS. THEN MEASURE FROM THE LINE JUST CREATED (AND NOT FROM THE BOTTOM OF THE PANEL) UP TO THE TOP OF THE PANEL AND PLACE A MARK AT EACH ESTABLISHED POINT. THEN TAKE A STRAIGHT EDGE AND PENCIL TO CONNECT THE DOTS. ONCE ALL MEASUREMENTS ARE ESTABLISHED, CHECK ALL MEASUREMENTS. ONCE ALL MEASUREMENTS ARE VERIFIED TO BE CORRECT AND TRANSFERRED CORRECTLY, BEGIN CUTTING THE PANEL.

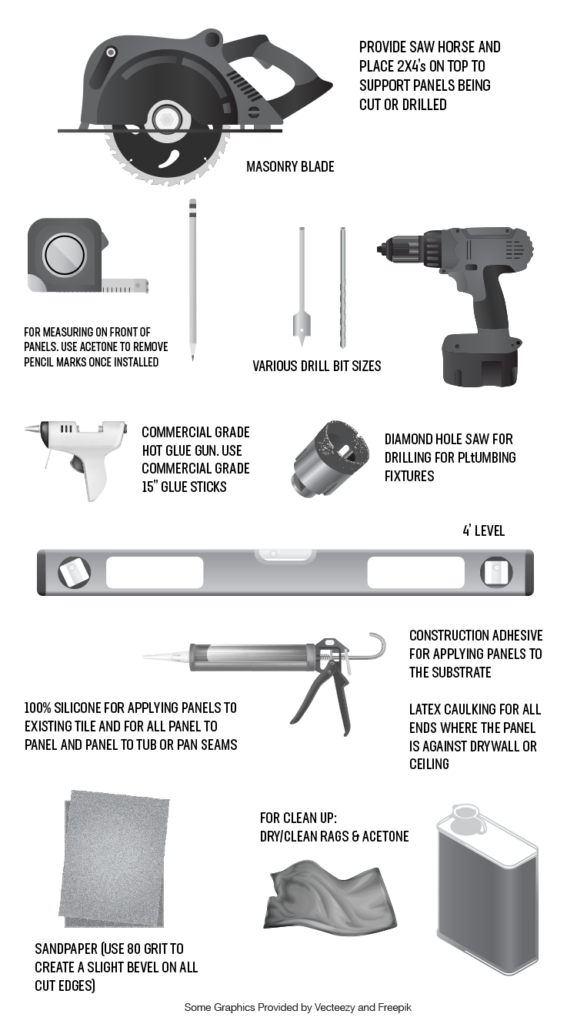

TO CUT THE PANEL, FIRST MAKE SURE THE PANEL IS WELL SUPPORTED BY 2X4’S, PLACED ON THE SAW HORSES. ONCE THE PANEL IS SUPPORTED, CUT ALONG THE ESTABLISHED LINES USING A CIRCULAR SAW WITH A MASONRY BLADE. IF CUTTING OFF MORE THAN ½” OF MATERIAL, MAKE SURE TO SUPPORT THE MATERIAL THAT IS BEING REMOVED TO AVOID THE MATERIAL BREAKING OFF BEFORE THE CUT HAS BEEN COMPLETED. IF THE MATERIAL BREAKS OR SNAPS BEFORE THE CUT IS COMPLETE, IT COULD BREAK INTO THE PANEL, CAUSING THE PANEL TO BE UNUSABLE.

6. Installing Back Panel

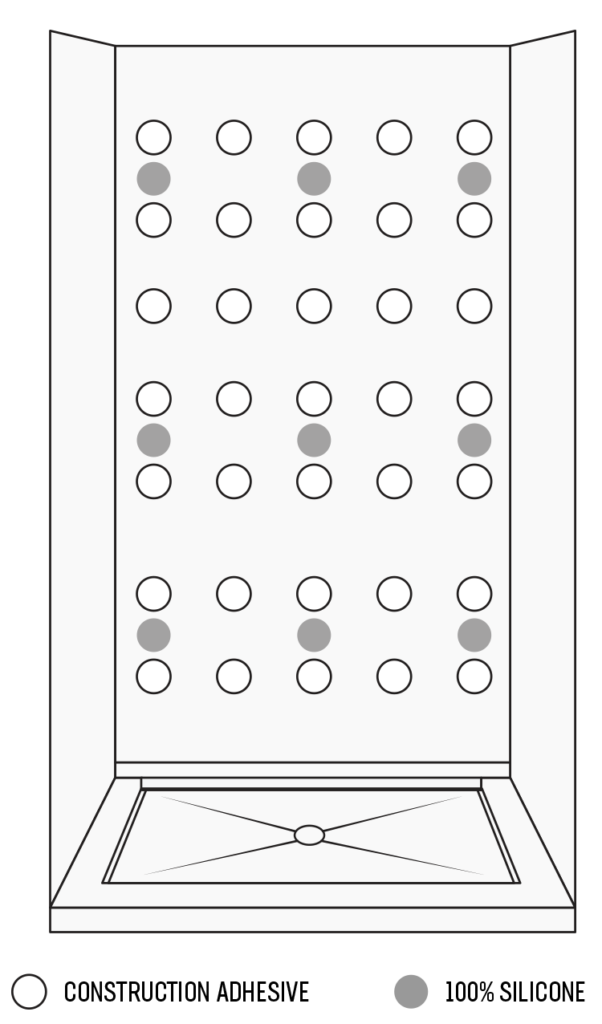

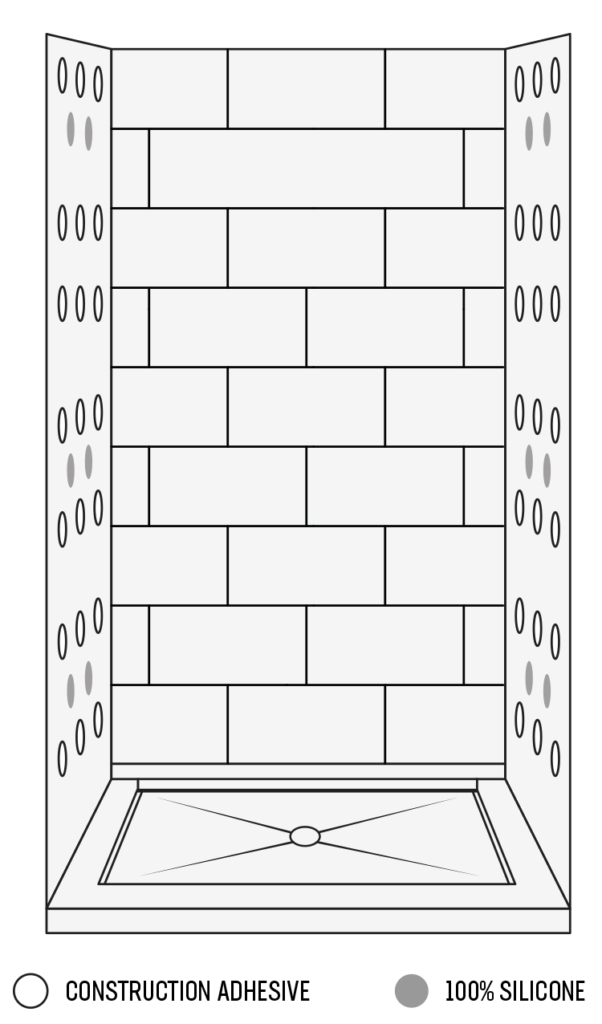

WHEN POSSIBLE, DRY FIT THE PANELS TO MAKE SURE OF A PROPER FIT, BEFORE APPLYING ADHESIVE TO THE WALL. ONCE A CONFIRM FIT, WIPE DOWN BOTH THE WALL AND BACK, UNFINISHED SIDE OF THE PANEL WITH ACETONE TO MAKE SURE BOTH ARE FREE OF DUST AND DEBRIS. THEN APPLY A GENEROUS AMOUNT OF ADHESIVE IN HEAVY CIRCLES AS ILLUSTRATED.

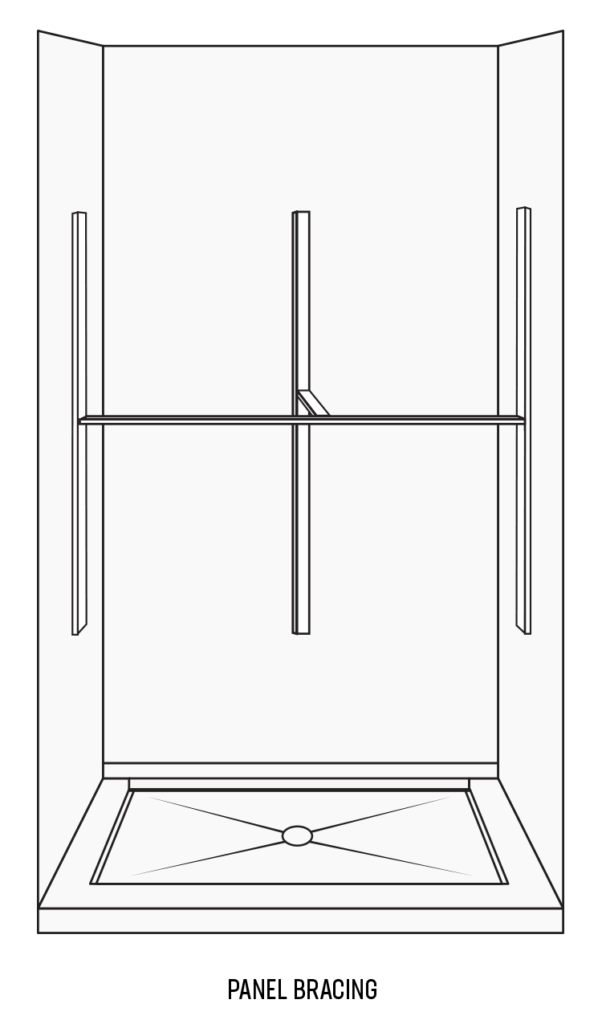

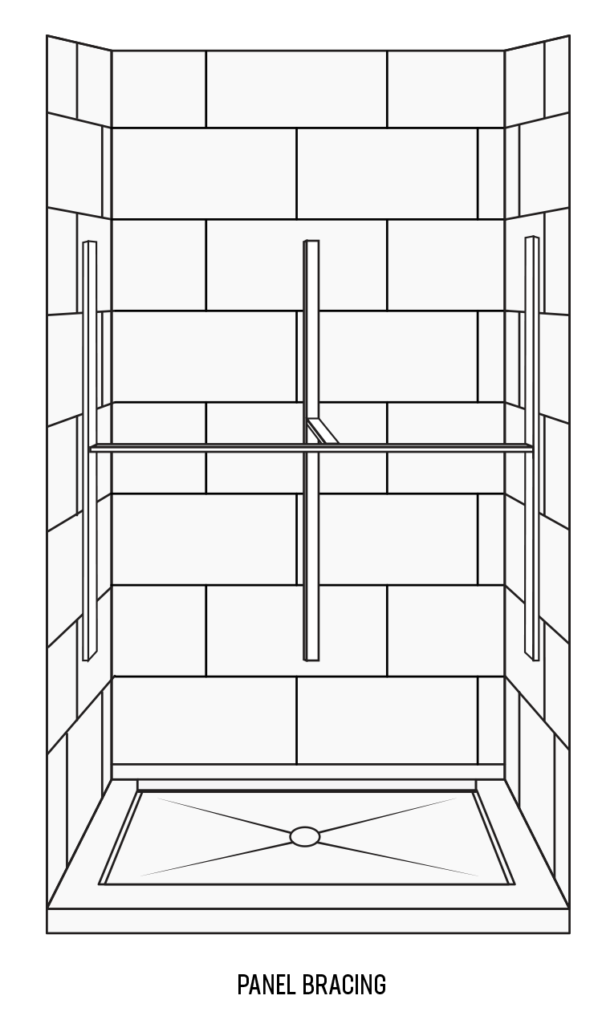

IF USING LARGE TUBES, THE BACK WALL SHOULD REQUIRE 1 AND EACH SIDEWALL SHOULD REQUIRE ½ TUBE OF ADHESIVE EACH. THE AMOUNT OF ADHESIVE SUGGESTED IS BASED ON A NORMAL INSTALLATION WITH SMOOTH, FLAT WALLS. SITE CONDITIONS COULD REQUIRE ADDITIONAL ADHESIVE. ONCE THE ADHESIVE IS APPLIED TO THE WALL, PUT THE PANEL IN PLACE, FIRMLY PRESSING INTO THE WALL TO DISTRIBUTE THE ADHESIVE. ONCE THE PANEL IS INSTALLED, ADD BRACING IN PLACE AS ILLUSTRATED, OR WHERE NECESSARY, TO FIRMLY HOLD THE PANEL IN PLACE, ALLOWING THE ADHESIVE TO DRY.

7. CL for Side Panel

LOCATE THE CL IN THE SAME MANNER AS STEP 2.

ONCE THE CL IS ESTABLISHED, LOCATE THE SIDE PANEL MEASUREMENTS IN THE SAME MANNER AS THE BACK PANEL (SIMILAR TO STEP 4).

NOTE:

IF INSTALLING TRIM, INSTALL BEFORE INSTALLING SIDE PANELS. INSTALL TRIM, USING 100{1fa982495514e501141dcc8d9a590336921c8ebd75a9bb2a135c5940f6282577} SILICONE AND HOT GLUE. MAKE SURE TRIM IS LEVEL, MEASURING FROM TOPS OF THE PANELS TO THE FLOOR (IF APPLICABLE)

NOTE:

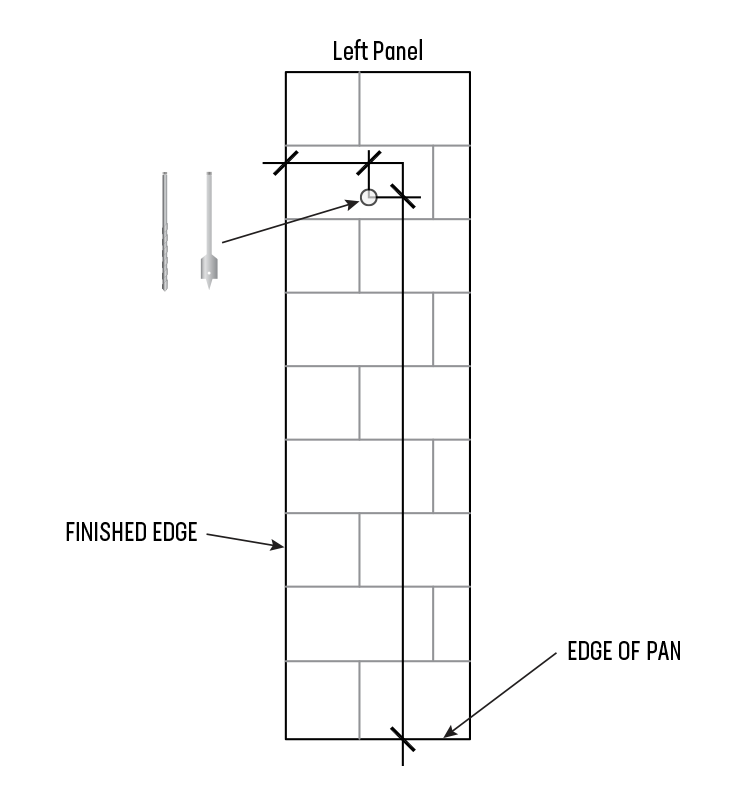

DO NOT PUT EXTREME PRESSURE ON THE DRILL, AS THE PANEL MAY BREAK WHEN THE BIT COMPLETES THE HOLE. TYPICALLY, IT IS REQUIRED TO DRILL ONE HOLE FOR THE SHOWER CONTROL VALVE AND ONE HOLE FOR THE SHOWERHEAD.

8. Drill Holes for Plumbing

ONCE THE PANELS HAVE BEEN CUT TO FIT, BEGIN LOCATING ALL PLUMBING FIXTURES AND DRILL THE CORRESPONDING HOLES IN THE PANEL. TO LOCATE THESE HOLES, MEASURE UP FROM THE EDGE OF THE PAN, AND OVER FROM THE FINISHED EDGE OF THE SIDE PANEL, TO THE CENTER OF THE INSTALLED FIXTURE AND TRANSFER THOSE MEASUREMENT ONTO THE PANEL. DETERMINE THE SIZE HOLE TO BE DRILLED AND CAREFULLY DRILL THE HOLE IN THE SPECIFIED LOCATION.

10. Installing Side Panel

THE SIDE PANELS WILL INSTALL IN THE SAME METHOD USED TO INSTALL THE BACK PANEL.

REFER TO STEP 6 FOR INSTRUCTIONS.

ONCE ALL PANELS HAVE BEEN INSTALLED, THEY SHOULD BE BRACED AS ILLUSTRATED, OR WHERE NECESSARY, TO MAKE SURE THE PANELS REMAIN IN PLACE WHILE THE ADHESIVE CURES. WHILE THIS ILLUSTRATION SHOWS SIMPLE BRACING, ADDITIONAL BRACING MAY BE REQUIRED BASED ON JOB SITE WALL CONDITIONS. WHILE THE BRACES SHOULD HOLD FIRMLY AGAINST THE PANELS, EXCESSIVE PRESSURE COULD DAMAGE OR CRACK THE PANELS. USE CAUTION WHEN PLACING THE BRACING.

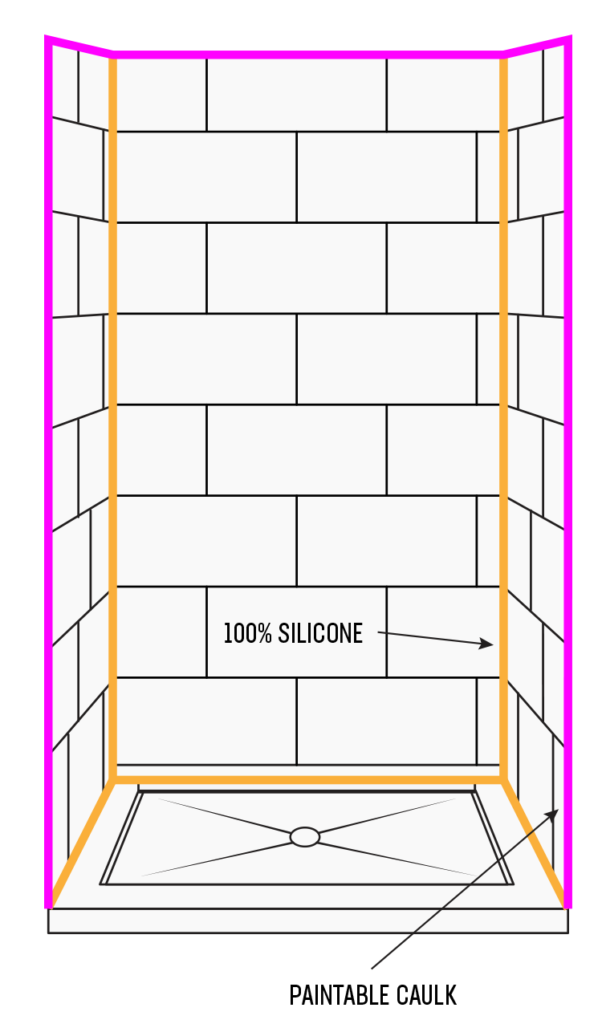

11. Caulk Joints

AFTER THE ADHESIVE HAS HAD TIME TO DRY (24 HOURS), REMOVE THE BRACING AND CAULK ALL OF THE JOINTS WHERE MARBLE TOUCHES MARBLE WITH 100{1fa982495514e501141dcc8d9a590336921c8ebd75a9bb2a135c5940f6282577} SILICONE THAT CLOSELY MATCHES THE COLOR OF THE MARBLE. CAULK THE CAST MARBLE PANEL TO THE SUBSTRATE WITH PAINTABLE LATEX CAULK.